Drill Acoustic perforated wood panels acoustic system

Are you looking for a real solution with a strong personality for your indoor environments, which combines excellent acoustic performances and extraordinary decorative qualities?

Then there is no doubt, Drill Acoustic perforated wood panels are just what you are looking for!

Drill Acoustic perforated panels, in fact, are the most suitable choice to obtain an optimal result from an acoustic point of view and meet a highly competitive aesthetic solution. The Drill Acoustic acoustic system was created to respond to the requests for functional and personalized acoustic conditioning, due to the high degree of sound absorption that characterizes it.

- Description

- Mounting system

- Customization of the wood perforated panels

- Materials and finishes

- Standard sizes

- Download

Description

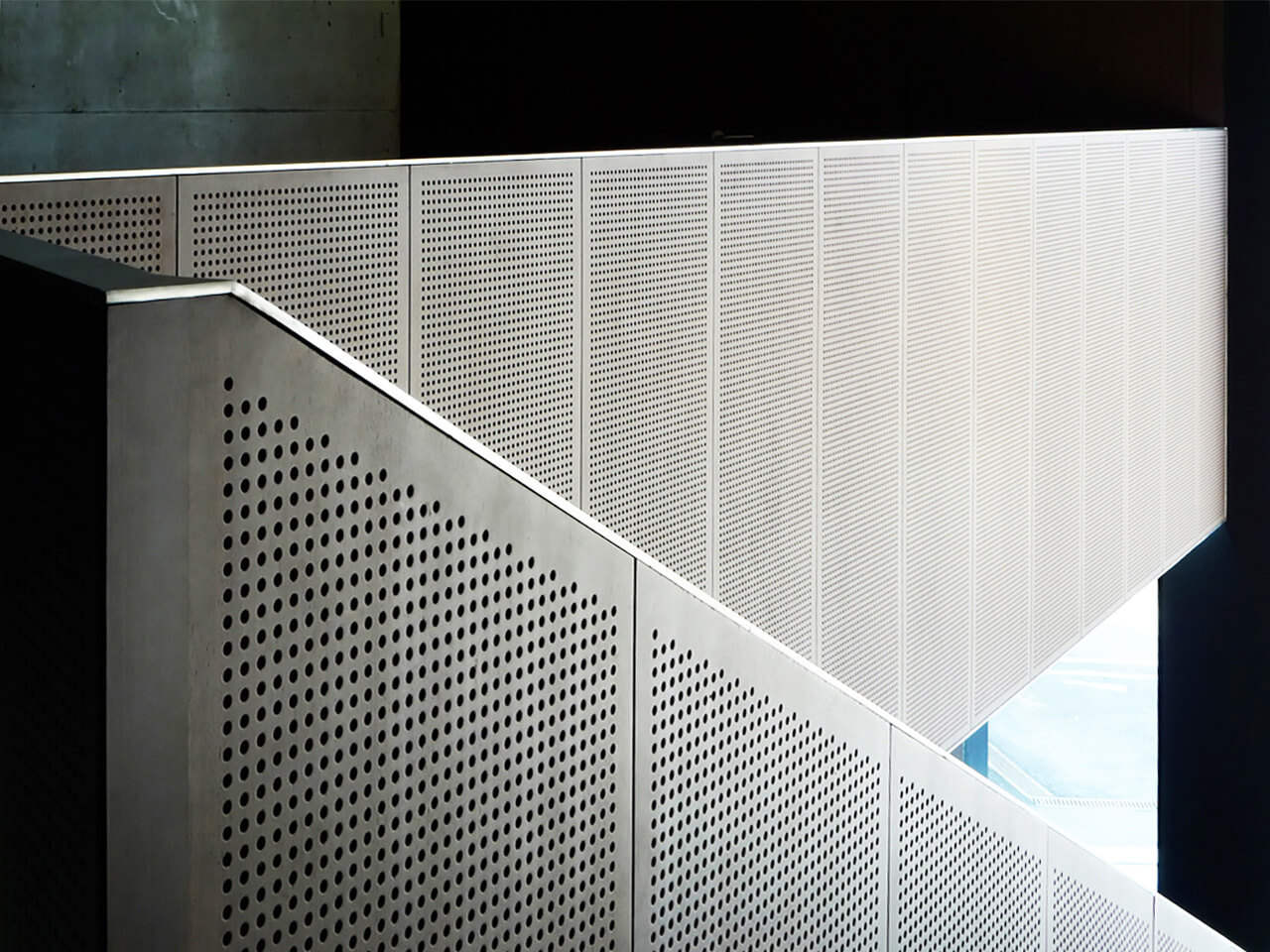

Drill Acoustic perforated wood panels act as an acoustic window thanks to the texture of holes that draw their surface. There are different types of Drill Acoustic panels, which differ according to their different perforation pattern and hole diameter. All this not only makes it possible to distinguish one panel from another, from the aesthetic point of view, but also provides a measure of the various levels of sound absorption that distinguish them.

Drill Acoustic acoustic panels allow you to correct and solve the problems caused by environmental noise in all those places where it is necessary to reduce the sound impact caused by the overlapping of numerous sound sources, while maintaining a high aesthetic profile. The Drill Acoustic coating, in fact, not only offers excellent acoustic performance, but also an elegant wood finish. It is available in a wide range of fine wood essences allowing you to achieve final results of the most varied tastes. Drill Acoustic panels are particularly suitable for restaurants, offices, conference rooms and meeting rooms, university classrooms, waiting rooms and all those environments for collective use.

Mounting system

Perforated wood panels are applicable to the wall and ceiling. Various mounting systems are available which can be inspectable and not inspectable depending on the type of fixing:

- wall: mounting profiles made of extruded aluminum (Tecalum) are used. The milled edges of the panels are mechanized for an invisible fixing (not inspectable)

- Ceiling: we adapt the panels to all existing fastening systems and profiles on the market. Modular mounting profiles type T24 made of steel are used. The edges of the panels are mechanized for visible or invisible fixing.

For an optimal acoustic absorption coefficient in class “A” it is necessary to provide a space of at least 30/40 mm between the wall and the back of the panels for the insertion of a mineral fiber or polyester mattress with a density of 30- 40 kg / m3.

Customization of the wood perforated panels

The most frequent drilling diameters are 5 and 8 mm with a drilling distance of 16 or 32 mm in an aligned or alternating position. It is also possible to make perforations of different diameters on each side. The perforations can be customized to reproduce an image by changing the diameters.

Drill Acoustic acoustic panels can be fully or partially perforated, depending on the desired design. It is possible to incorporate special millings to integrate chandeliers or other systems.

We also offer other wood acoustic panels:

Materials and finishes

Our perforated panels are made of standard or fireproof MDF wood fiber. The surface finishes of the panels are available in a wide range of natural wood veneers, painted or lacquered in RAL or NCS, in HPL laminate or in melamine.

Drill Acoustic panels can also be made of mass-colored MDF or plywood. We have a series of accessories to improve the finishes of the installations (decorative panels, skirting boards, corners, profiles and finishing edges, etc.).

Standard sizes

Panels of 2400 x 1200, 2400 x 600, 2400 x 300, 1200 x 600, 600 x 600, thickness of 16 and 12 mm.

The thickness of 16 mm is usually used on the wall for greater resistance, while that of 12 mm is used on the ceiling to contain the weight of the false ceiling.